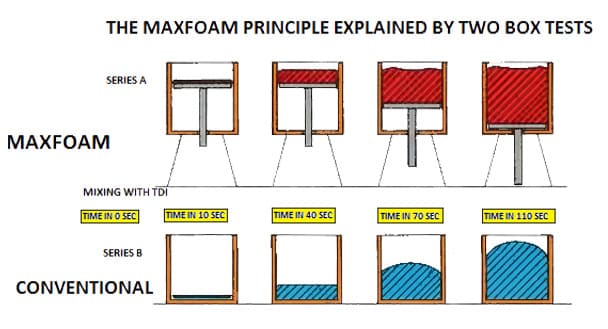

To illustrate the principle of the conventional process compared with the Maxfoam Process two series of laboratory box tests were carried out using a similar formulation. Series A are tests carried out in a box with a downwards moving bottom to simulate the effect of the fa Ilplate. The foaming liquid is poured on to the piston ten seconds after mixing in the T.D.I. The foaming liquid will rise upward starting from the 70% level of the final block height. After forty seconds the foam reaches the final height and then the piston is pulled downward at a synchronized speed which compensates for the vertical rise. After 110 seconds the rise is finished. This is indicated by the arrival of the piston at the bottom of the box. On the production machine the full rise is achieved when the foam arrives at the end of the fall plate and meets the horizontal conveyor. Series B shows what happens when foam rises in the conventional way-the friction of the sidewa II will increase with the higher block height and the resultant cross-section is domed.