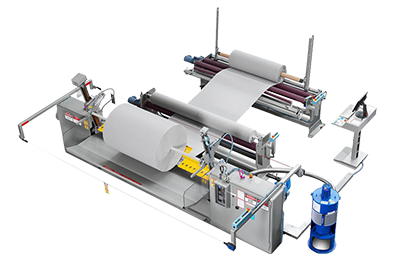

The Polyurethane foam material cylinder is fixed to a peeling mandrel and rotated via a motorized feed roller. The desired layer thickness can be easily set by using change gears or alternatively electronically. The Polyurethane material cylinder is moved vertically via lifting spindles, before being evenly fed into the circulating sharpened bandknife. The peeled foam can then be continually wound up by the next device.

Cut Thin Material Layers With Precision

The side spindle guides allow the material cylinder to be lowered smoothly and evenly. Hardened and ground bandknife guides ensure that the bandknife is guided with precision. An automatic bandknife adjustment (electronic eye) ensures that the bandknife is always in the perfect position. The band knife perfect location is guaranteeing a precise cutting result. The integrated grinding device to ensure a consistently high cutting quality. This peeling process can produce continuous rolls up to 300 meters length without any joint (depending on thickness).